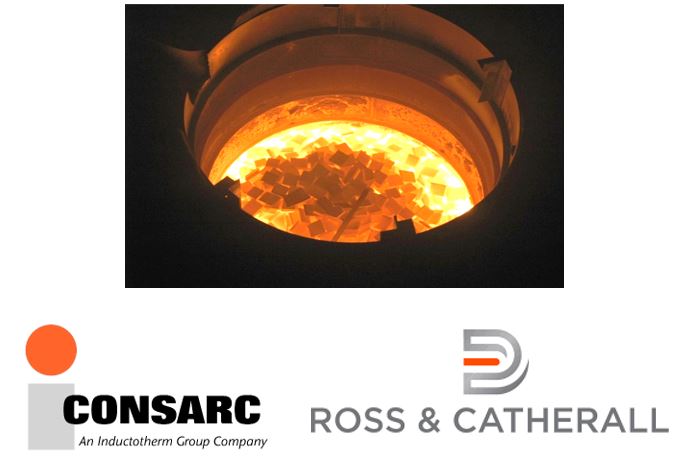

In June 2021 Consarc were delighted to secure an order from Ross & Catherall (part of the Doncasters Group) for a 5T Vacuum Induction Melting furnace.

The furnace represents the latest VIM design specifically configured for the highest quality, most efficient masteralloy production of highly specialised nickel and cobalt-based superalloy barstock, with features including:

- VIM layout tailored to suit the existing Ross & Catherall facility for optimised and efficient product flow.

- Consarc rapid exchange furnace design for rapid maintenance turn-around and maximised furnace up-time.

- Consarc’s short tundish VIM design with multiple filtration to ensure optimum metallurgical quality and cleanliness.

- Multi-charging system capability for shortest melting, safety considerations and flexibility.

- Dry vacuum pumping system and latest high vacuum oil vapour booster technology incorporating energy saving modules to reduce operating costs.

- Inductotherm solid state induction power supply, including:

- High melting efficiency and Power Factor throughout total operation.

- Integrated Unidirectional Stirring system to provide enhanced metal stirring / agitation for shortest degassing times with the highest possible electrical efficiency.

- Remote control of melting operations and extensive safety design features.

The VIM furnace shall be supplied in 2022 with full operation planned at start of 2023.

This investment represents the first large-scale masteralloy VIM investment in a number of years in Europe and enables Ross & Catherall to strengthen their position across the aerospace, IGT, automotive and other casting market sectors.

This order represents a further commitment to Consarc from the Doncasters Group, with recent order placement for a new 300lb Equiax vacuum casting furnace at its investment casting facility in Alabama and a long history of equipment supply in the UK and North America.