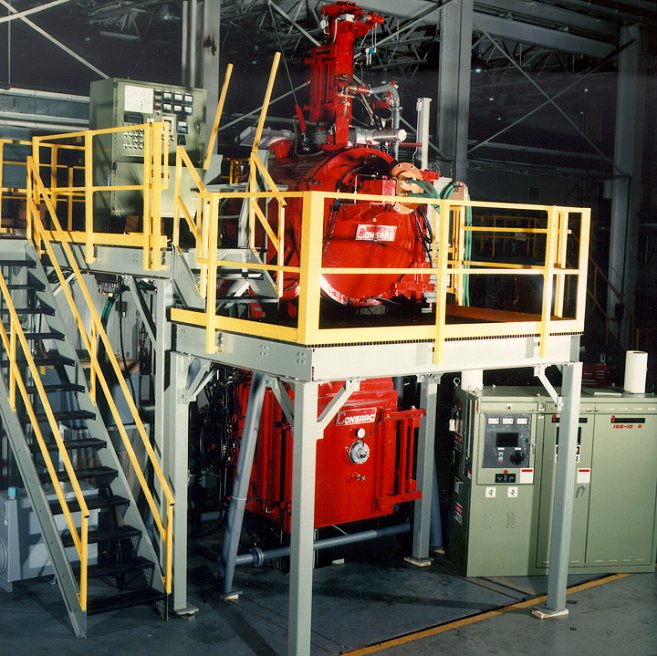

Two Chamber Vertical Induction Skull Melting Furnace

Consarc offers Induction Skull Melting (ISM) furnaces which is a method of melting metals in a segmented water-cooled copper vessel while under vacuum or controlled atmosphere using an induction coil. Consarc’s two chamber vertical furnaces are excellent for the production of high volume castings with great variations in mold height. Consarc ISM furnaces provide superior chemical and thermal homogenaity when compared to more traditional methods of melting reactive materials such as arc skull casting.

Features

- Semi-Continuous operation

- High Throughput

- No vacuum break of the melt chamber to charge furnace

- Good for alloys that require highest possible vacuum levels

- Pit and High Overhead Clearance Required

Tech Specs

Capacities: 5kg – 100kg+

Vacuum Levels: up to 1×10-5 torr

Copper Crucible from a single forged piece of material

CCTV System for viewing melt remotely

Remote controls for safe operation

Vacuum isolated mold chamber

Accessories

- Cup charger

- Bridge breaker

- Immersion Thermocouple

- Pyrometer

- Vacuum Isolated Bulk Charger

- High Vacuum Pumps (Diffusion or Oil Vapor Booster)